Diaphragm Disc Couplings

Features

Precise transmission characteristics, high torsional rigidity, high sensitivity, zero backlash

The forward and reverse characteristics are the same

No lubrication is required, saving operating costs

Small radial size, small size, and lightweight

Corrosion resistance, high and low-temperature resistance, suitable for all kinds of extremely harsh working conditions (-30°~+200°; humid, acid-base environment)

Effectively correct axial, radial, and angular installation deviations

Reduce heat conduction error and ensure transmission accuracy

High-quality stainless-steel material SUS304 from Japan

After simulation force analysis and design optimization, a long lifetime

Good flatness and position to ensure the best assembly quality

REACH® Diaphragm Couplings Types

-

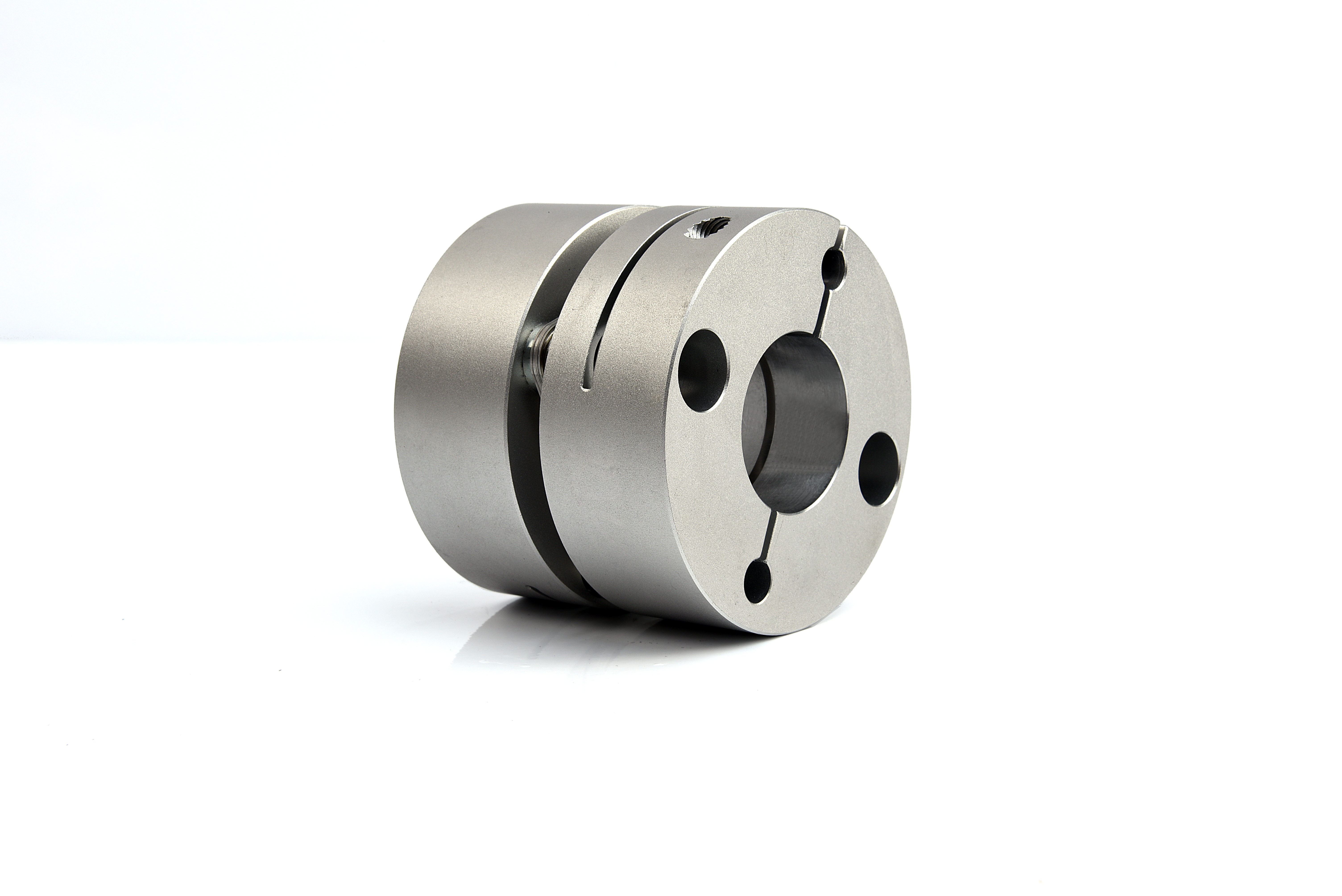

Diaphragm Couplings RDC Series

Technical data download

Technical data downloadStrong deviation correction functions;

High torsional stiffness;

Compact structure;

Single and double diaphragm available;

Especially suitable for precision transmission. -

Diaphragm Couplings RIC series

Technical data download

Technical data downloadRIC diaphragm coupling is made of high-strength aluminum alloy material, high torque stiffness and high response speed, with extremely low moment of inertia;

The flexible parts are made of stainless steel, with compact structure and no backlash;

Correcting axial, radial, and angular installation deviations and compound mounting misalignments;

Higher rigid single diaphragm, double diaphragm structure optional;

Centering assembly of special jigs to ensure the coaxiality of the holes at both ends. -

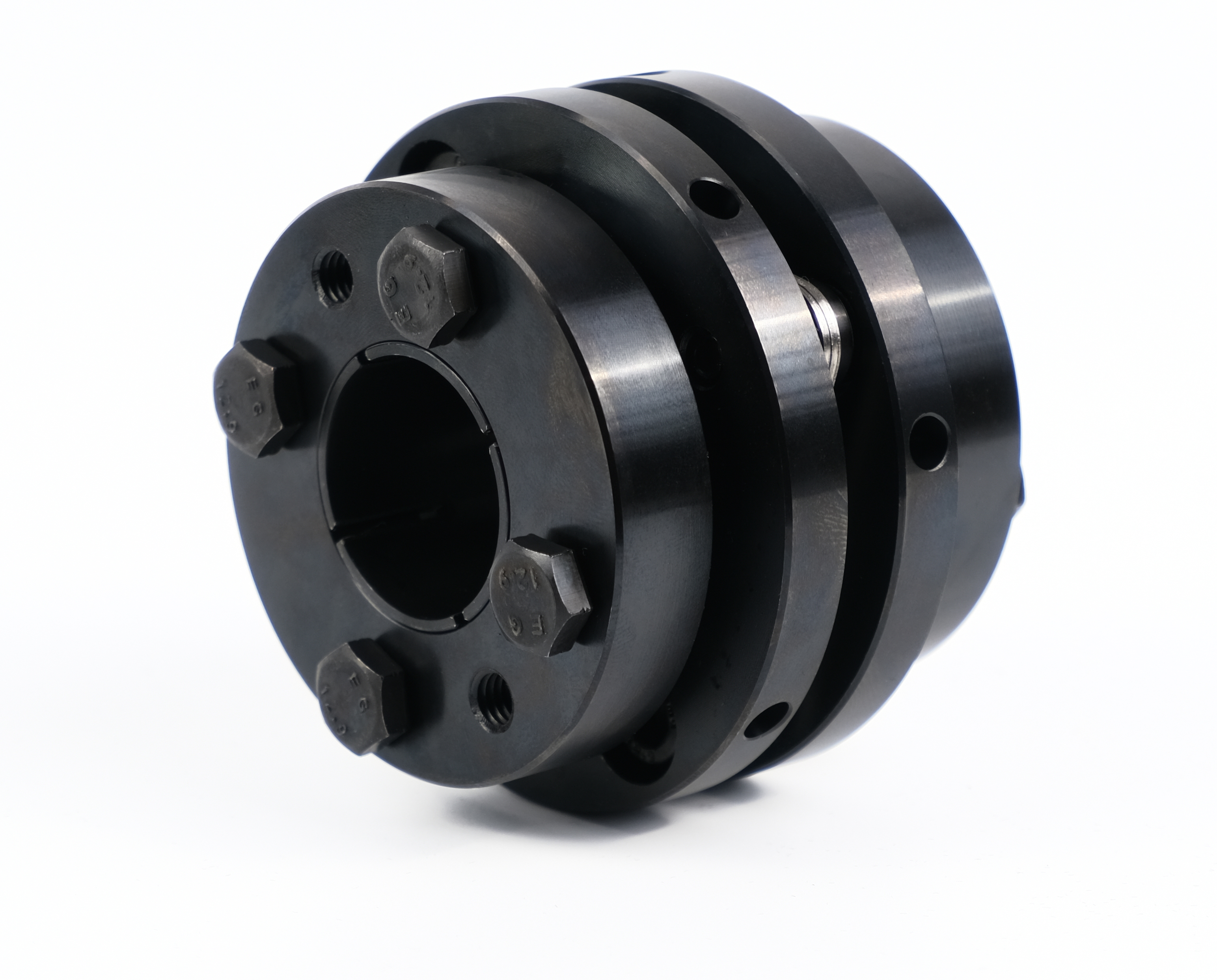

Diaphragm Couplings REC series

Technical data download

Technical data downloadSuper rigid;

Large shaft diameter available;

Shaft structure is simple and symmetrical;

The flexible parts are made of stainless steel, with compact structure and no backlash;

Correcting axial, radial, and angular installation deviations and compound mounting misalignments;

The centering assembly of the smelter ensures the original coaxiality of the two end holes.