Contact: sales@reachmachienry.com

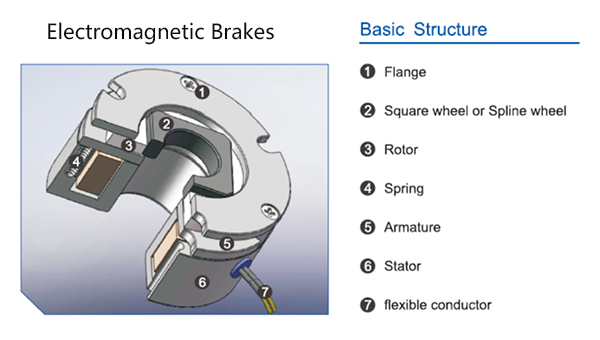

Servo brake is a component that is released by electricity, also known as electromagnetic brake.

Servo brake is mainly composed of a cover plate, a connecting hub (square or spline), friction disk components, springs, an armature, a stator and flexible conductor. It is generally installed at the rear end of the motor and acts on the main shaft of the motor to prevent the motor from sliding down due to sudden power failure and causing danger.

The servo brake sometimes encounters the situation that it does not operate or is not powered on. First of all, the user can check by himself to determine whether the wire of the servo brake is broken.

Usually, the soft wire of the servo brake is very thin, and the coil of the brake is soldered with the soft wire, and the coil wire is usually not allowed to be pulled vigorously. The pulling force should not exceed 80N. If it exceeds this force during installation and use, it is very easy to be broken, which will cause the brake to be non-conductive and unable to work normally.

The servo brake of REACH brand has the characteristics of small volume, high torque, long service life, and low noise, etc., and has reached long-term strategic cooperation with many well-known enterprises at home and abroad.

REACH servo brakes make movement safer.

Post time: May-15-2023