sales@reachmachinery.com

Locking Assemblies are keyless connecting devices that generate significant clamping forces between the inner ring and the shaft, as well as the outer ring and the hub, through the action of high-strength tension bolts. This achieves a keyless connection between the components and the shaft. Truss robots, on the other hand, are automated devices with simple structures, flexible movements, and lightweight designs. The application of Locking Assemblies on truss robots involves utilizing the technology in critical areas of the robot to achieve higher precision, reliability, and efficiency.

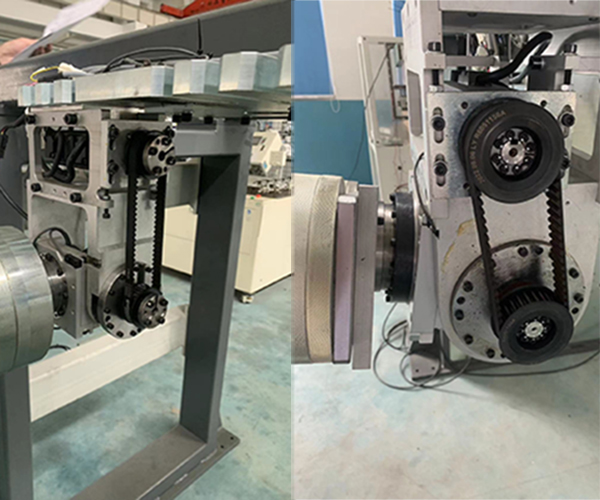

Locking Assemblies from Reach Machinery

The application of Locking Assemblies on truss robots offers the following advantages:

Improved positioning accuracy: Locking Assemblies provide a rigid connection that ensures the robot’s components do not loosen during movement, thereby enhancing the robot’s positioning accuracy.

Enhanced reliability: Locking Assemblies effectively prevent part loosening and detachment, ensuring the stability and reliability of the robot during prolonged operation.

Quick disassembly and replacement: The design of Locking Assemblies facilitates convenient disassembly and replacement of parts, thereby improving maintenance and servicing efficiency and reducing downtime.

Cost reduction: Locking Assemblies technology eliminates the need for complex threading, welding, or adhesive processes, reducing material and labor costs in the production process.

The application of Locking Assemblies on truss robots spans various fields, including:

Automotive manufacturing: The application of Locking Assemblies on automotive assembly lines ensures the stability and precision of robots during the assembly process, thereby increasing automotive production efficiency.

Electronics industry: Locking Assemblies can be used in the assembly process of electronic devices to ensure precise positioning of precision components, thereby improving the quality and production efficiency of electronic products.

Medical device manufacturing: Locking Assemblies can be applied in the production process of medical devices to ensure reliable connections of critical components, thereby enhancing product safety and stability.

The application of Locking Assemblies on truss robots provides customers with an efficient and reliable automation solution. Through the use of Locking Assemblies technology, truss robots can achieve higher precision and reliability while reducing production costs, thereby enhancing customers’ productivity. In future industrial developments, the application of Locking Assemblies on truss robots will play an increasingly important role, providing enterprises with a greater competitive advantage.

Post time: Jul-10-2023