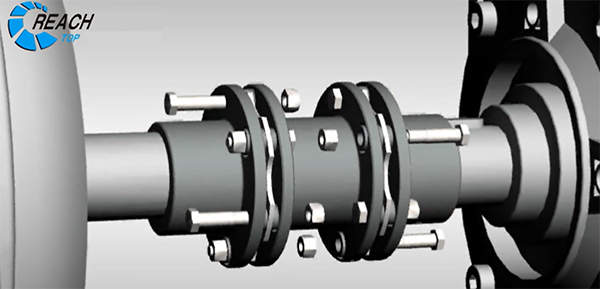

REACH Diaphragm coupling is a commonly used mechanical transmission device, the quality and skills of its assembly have an important impact on its normal operation and life. Among them, the temperature difference assembly method is one of the commonly used assembly skills.

The temperature difference assembly method causes the diaphragm coupling or the shaft to undergo thermal expansion or cold contraction by means of heating or cooling, thereby facilitating the assembly of the wheel coupling to the shaft. Compared with the static press-in method and the dynamic press-in method, the temperature difference assembly method has many advantages and is especially suitable for hubs made of brittle materials. Generally, heating is used for temperature difference assembly, and cooling is rarely used. There are many heating methods; the common ones are oil bath heating and torch baking. The maximum temperature of the oil bath depends on the nature of the oil, generally below 200°C. When using other heating methods, the temperature of the coupling can exceed 200°C, but considering the influence of metallography and heat treatment, the heating temperature of the disc coupling should not exceed 430°C, otherwise it will cause changes in the internal structure of the steel. Therefore, for safety reasons, the upper limit of the heating temperature of the coupling should be below 400°C. For Reach diaphragm couplings, the actual required heating temperature can be calculated according to the fit interference value between the coupling and the shaft and the requirements during assembly. The temperature difference assembly method is a commonly used technique in the assembly of diaphragm couplings. Reasonable mastery and application of this method can effectively improve assembly quality and efficiency.

The above is the introduction of the temperature difference assembly method, one of the assembly skills of REACH diaphragm coupling or disc coupling, and hope it will be helpful to you!

Contact us at sales@reachmachinery.com to get more assembly tips from us!

Post time: Jun-26-2023