Contact: sales@reachmachinery.com

Collaborative robots, also known as cobots, are revolutionizing manufacturing by allowing humans and machines to work together in a safe and efficient manner. Harmonic reducers are key components that help cobots achieve precision and accuracy. In this article, we discuss the role of harmonic reducers in collaborative robots and how they work.

So, what is a harmonic reducer?

A harmonic reducer (also known as a harmonic drive gear) is a mechanical gear system that uses a flexible spline with external teeth deformed by a rotating oval plug to mesh with the internal gear teeth of the external spline.

The main components of the harmonic reducer: a wave generator, flex spline, and circular spline.

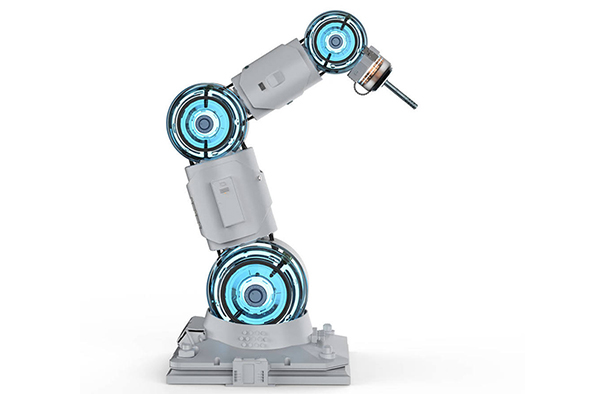

Harmonic Reducer from Reach Machinery

Harmonic reducers are commonly used in robotics, aerospace, medical equipment, and automation equipment because they provide high precision, accuracy, and repeatability. They also have a high torque-to-weight ratio, making them ideal for applications where weight and space are at a premium.

How Do Collaborative Robots Use Harmonic Reducers?

In collaborative robots, harmonic reducers are often used to control the motion of robotic arms. The harmonic reducer is connected to the motor and the robot arm, enabling the robot to move with high precision and accuracy. Harmonic reducers also provide high torque output, critical for tasks that require robots to move heavy objects.

Another benefit of using a harmonic reducer in a cobot is that it enables smoother motion. The flexible cups of the harmonic reducer absorb shock and vibration, reducing wear and extending the life of the arm.

In summary

Harmonic reducers are key components of collaborative robots, enabling them to achieve high precision, accuracy, and repeatability. By using harmonic reducers, cobots can perform tasks more efficiently, making them an essential tool in manufacturing.

Experience precision and reliability with Reach – the harmonic reducersultimate solution for your motion control needs.

Post time: May-10-2023