contact: sales@reachmachinery.com

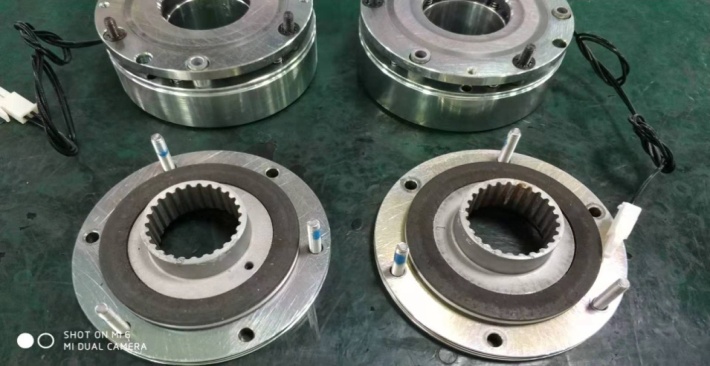

For many industries, electromagnetic brakes are essential mechanical components that improve the control performance of various equipment. However, there is often a fatal quality problem of brake adhesion or jamming, which seriously affects the safety and service life of the equipment.

So why do electromagnetic brakes have adhesion problems? This issue is usually related to the core component of the brake – the friction plate. The brake friction plate is very sensitive to water and oil. If the brake has been stored for a long time or stored in an environment with heavy water vapor, the friction plate is likely to absorb water, which may cause slight or serious adhesion problems.

To solve the problem of adhesion of electromagnetic brakes, the following specific solutions are provided:

1. Motor brake storage: Keep storing in dry environment. If slight adhesion, the brake can be energized and the rotor or motor can be lightly tapped to relieve the slight adhesion. However, if the friction plate absorbs too much water, it will cause serious adhesion, and the brake needs to be returned to the brake manufacturer for friction plate replacement.

2. Motor brake friction plate has oil or condensation: If the brake is not properly protected, the friction plate has oil or foreign matter, or there is condensation, the brake will have adhesion, jamming, or abnormal torque. At this time, we need to remove the brake, eliminate the specific fault cause, and confirm that the brake is undamaged and the friction surface is free of oil stains, foreign matter, and water before continuing to use it.

Get more information about REACH BRAKES

Get more information about REACH BRAKES

REACH Machinery with 24-year manufacturing experience of motor brake, can help you solve any problems of motor brakes.

Post time: May-19-2023