Contact: sales@reachmachinery.com

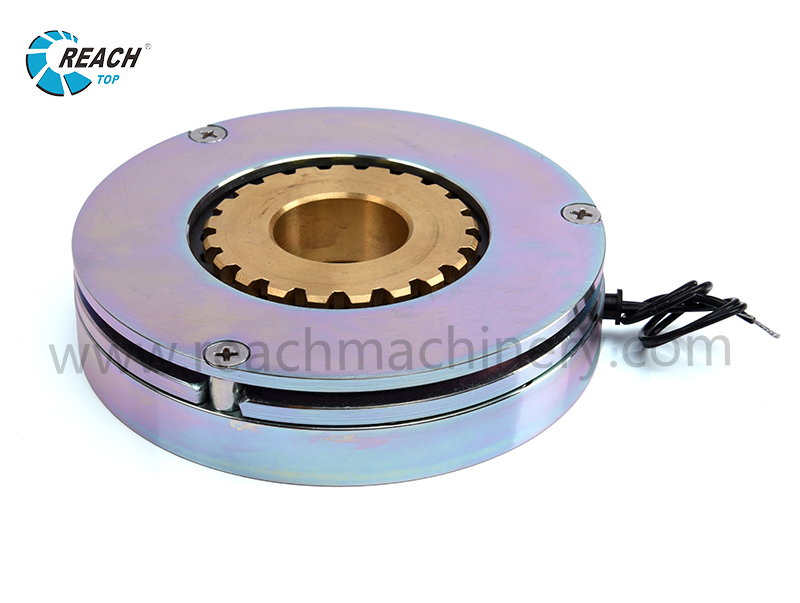

The servo motor brake, also known as holding brake or holding electromagnet, is a type of fail-safe brake. If you choose a servo motor with a built-in brake, the electromagnetic brake is included inside the motor. The normal working condition of the servo motor brake is to lock the rotor shaft of the motor after it comes to a stop and cut off the power, preventing the motor shaft from rotating within the rated torque range under power-off condition. Meanwhile, the servo brake itself has a certain emergency stop capability, which can respond to sudden power off during motor operation and the need for braking.

The servo motor brake is generally located perpendicular to the servo axis to prevent dager caused by load rotation duen to gravity when sudden power failure occurs.

Therefore, the servo motor brake is a safety-critical component. What are its key parameters?

Voltage: The voltage for most servo motors is typically 24V.

Torque: Different bases have different requirements for the brake torque. Therefore, it is necessary to confirm whether the selected brake matches the torque required by the motor. Otherwise, the motor may not be able to brake properly.

And the torque needs to be divided into static torque (holding brake) and dynamic torque (deceleration brake). We also need to test the torque data values at different temperatures and humidities. The torque of this brake is considered qualified only when it meets the torque requirements under various environmental conditions.

Wire length: This parameter is to facilitate the connection between the brake and the motor. Different motors may have different requirements for wire length.

Reach Machinery Co.,Ltd. can provide customized services according to customer requirements.

In conclusion, when selecting a servo motor brake, it is essential to consider these key parameters to ensure the safety and effectiveness of the brake.

Post time: May-05-2023