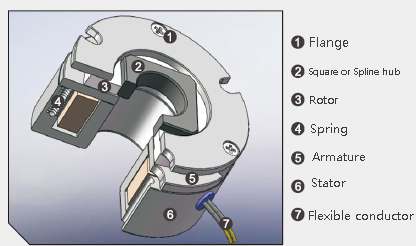

Servo brakes are mainly used in robots, industrial mechanical arms, machine tools, and automated production lines. The rotating rotor is tightly clamped between the armature and the cover plate. When the brake needs to be released, the stator is connected to DC, and the generated magnetic field attracts the armature to move towards the stator. When the armature moves, the spring is compressed. At this time, the rotor is released and the brake is released.

Servo brakes have many advantages. It can control the speed accurately, control the brakes more precisely, save energy, and improve the performance of the motor. It is widely used in machine tools, robots, industrial automation, aerospace, etc.

In the market, the quality of servo brakes varies. Apart from performance, the most intuitive difference is the structural design. Some have a hexagonal design on the hub, and some have a square design. What is the difference between a hexagonal design and a square design? Why is a square design better? The reasons are as follows:

- The servo brake is mainly used in high-speed applications. If it is hexagonal, the friction between the parts will easily make it round. T diherect result is that the square wheel moves, but the friction disc does not move, and the torque cannot be transmitted.

- The rotation backlash of the hexagonal hub is too large, so the positioning accuracy will be affected.

The servo brakes of Chengdu REACH machinery Co., Ltd. are all designed with square wheels to ensure the quality of the products!

Post time: Jul-22-2023