REACH GR Elastomer Jaw Couplings

Features

● Small and compact structure, low weight and large transmission torque, which can effectively improve the movement quality and stability of the machine, and absorb the impact caused by the uneven operation of the power machine.

● Effective protection capability to damp and reduce vibration and shock appearing during motion, effectively correcting axial, radial and angular installation deviations.

● The maximum torsion angle of claw couplings larger than 14 can reach 5°, and can be installed horizontally or vertically

Advantages

● Mass production of metal parts, self-produced elastomers, using high-quality German TPU materials

● Explosion-proof certification

● Instantly exceed 50% of the maximum torque value can still meet the transmission requirements

● Passed the high and low temperature life test, can still be used under the maximum load

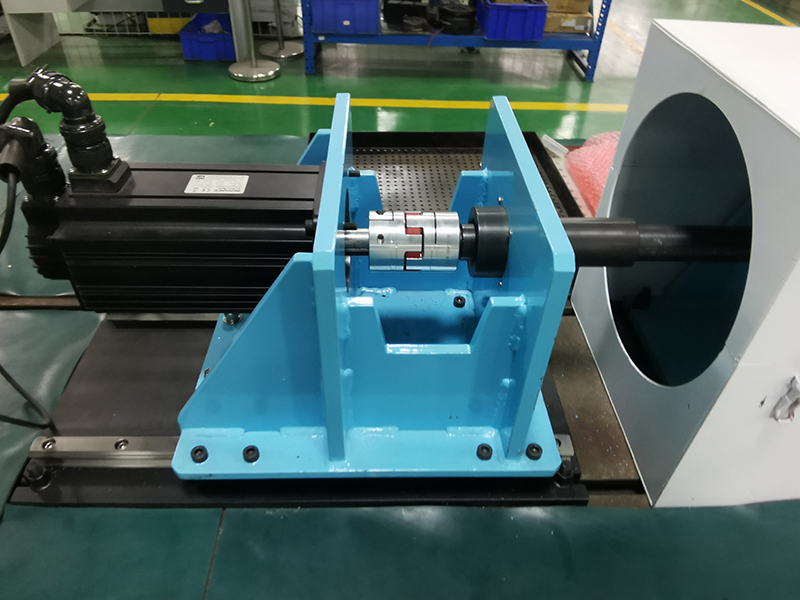

● Perfect coupling test platform

REACH® GR Elastomer Jaw Couplings Application Examples

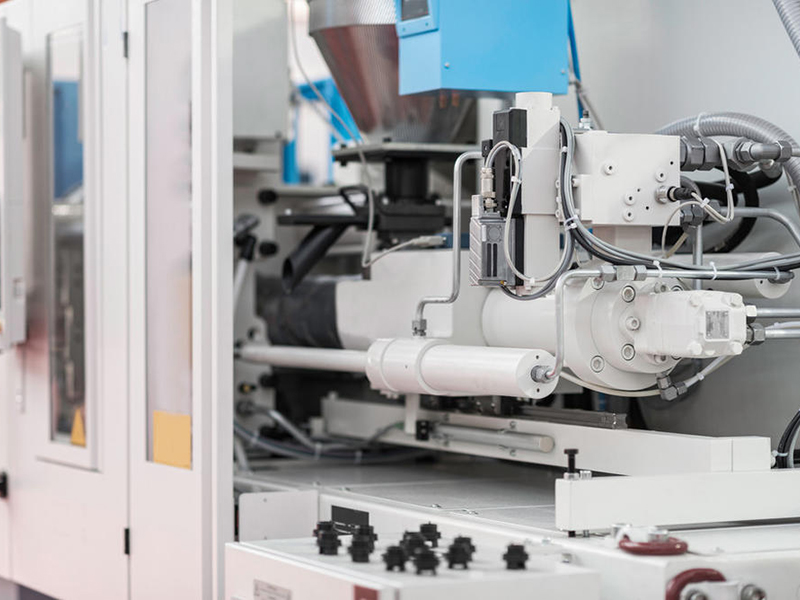

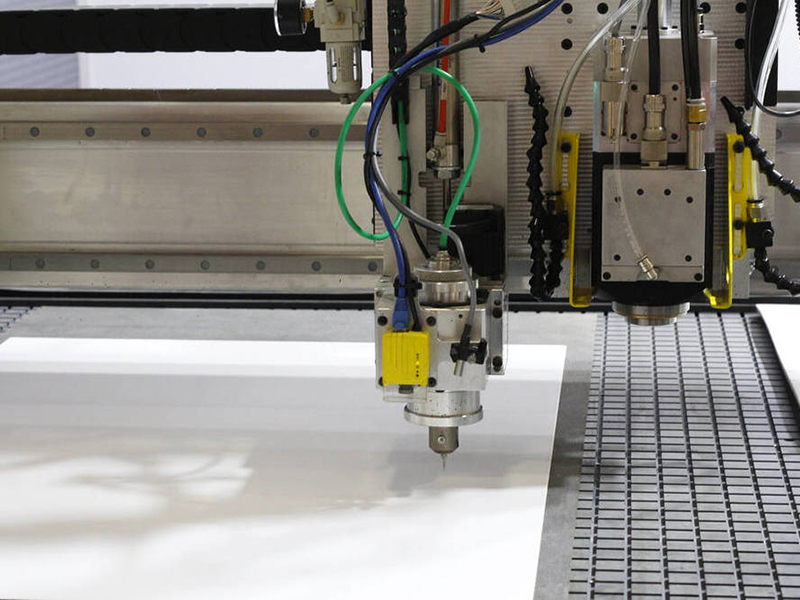

GR Couplings Applications: Compressors, Towers, Pumps, Lifts,Injection molding machines and other general transmission industries.

GR Elastomer Jaw Couplings Types

-

GR Elastomer Couplings Standard Type

Technical data download

Technical data downloadWidely used under mechanical and hydraulic pressure circumstances;

No need to maintain by using steel in conjunction with polyurethane; Compensate relevant deviation, buffer and absorb vibration;

Better insulate electricity;

Easy mounting by inserting at axial direction;

Aperture tolerance: ISO H7; Keyslot tolerance: DIN 6886/1 Js9;

Taper and inch bores are designed for option. -

GR Elastomer Couplings Double Section Type

Technical data download

Technical data downloadCompensate very large deviation in mounting;

Structured in 2 sections of 3 parts;

Reduce noise by dampening vibration;

Better insulate electricity;

Restoring force from deviation is very small;

Extend service life adjacent parts;

Aperture tolerance: ISO H7; Keyslot tolerance: N6885/1 Js9;

Taper and inch bores are designed for option. -

GR Elastomer Couplings Flang Type

Technical data download

Technical data downloadStructure FLA and FLB are applied to heavy machinery industry;

Easily dismantle: just remove flange for radial mounting and replace the spider without moving equipment at driving and driven ends;

Materials: 4N steel, 3Na Steel and GGG-40 cast iron;

Easy assembly by inserting axially;

Aperture tolerance: ISO H7; Keyslot tolerance: DIN6885/1 Js9;

Taper or imperial bores are for option. -

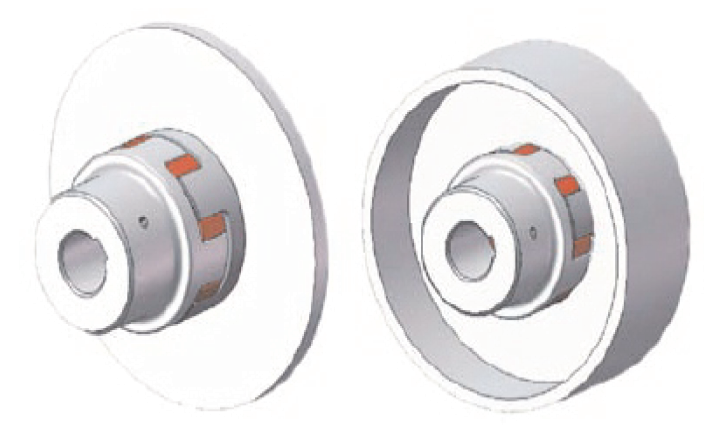

GR Elastomer Couplings Braking Type

Technical data download

Technical data downloadCoupling with brake drum is designed to application where braking is realized by holding two external brake drums for friction;

Coupling with brake disc is designed to caliper brake;

Brake drum or disc should be mounted at the shaft end with largest moment of inertia;

Max braking torque should not exceed max torque of the coupling;

The maximum brake torque shall not exceed the maximum one of coupling;

Aperture tolerance: ISO H7; Keyslot width: DIN 6885/1, and tolerance JS9. -

GR Elastomer Couplings DK Type

Technical data download

Technical data downloadSmall size and small rotation inertia;

Free maintenance and easy for visual check;

Elastomer with different hardness for option;

Finished bore tolerance respects ISO H7, excluding clamping shaft sleeve, DIN6885/1 for bore diameter above JS9 for keyway.