RCSG Cup-shaped Strain Wave Gear

Working Principle

Harmonic reduce working principle refers to the use of relative motion of the flexspline, circular spline and wave generator. The motion and power transmission is mainly achieved by using the controlled elastic deformation of the flexspline. The elliptical cams in the wave generator rotate inside the flexspline to deform the flexspline. While the teeth of the flexpline at the long end of the elliptical cam of the wave generator enter into engagement with the teeth of the circular spline, the teeth of the flexspline at the short end are disengaged from the teeth of the circular spline. For the teeth between the long and short axes of the wave generator, they are in the semi-engaged state of gradually entering engagement in different sections along the circumference of the flexspline and the circular spline, called engagement. And in the semi-engaged state of gradually exiting engagement, called engagement-out. When the wave generator rotates continuously, the flexspline continuously generates deformation, so that the teeth of the two wheels continuously change their original working state in four kinds of motion: engaging, meshing, engaging and disengaging, and generate the motion of misaligned teeth to realize the motion transmission from the active wave generator to the flexspline.

Features

Zero side gap, small backlash design, backlash is less than 20 arc seconds.

Long service life.

Standardized size, strong versatility

Low noise, low vibration, smooth running, stable performance, safe and reliable.

Applications

Strain wave gears are widely used in robots, humanoid robots, aerospace, semiconductor manufacturing equipment, laser equipment, medical equipment, metal processing machinery, drone servo motor, communication equipment, optical equipment, etc.

-

RCSG Strain Wave Gear

RCSG Strain Wave Gear

-

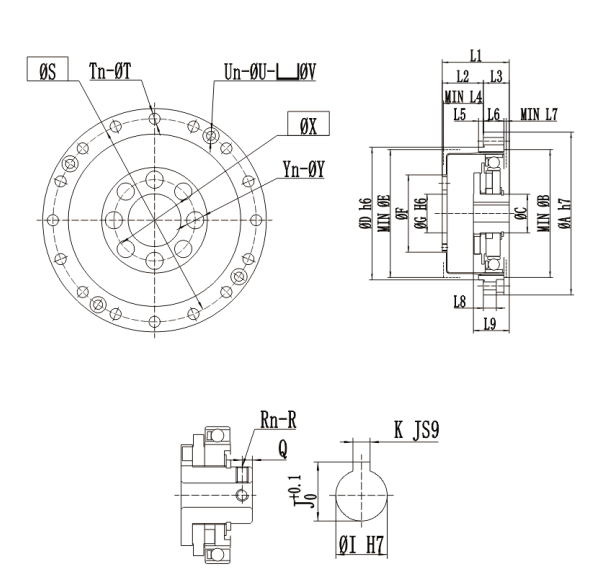

RCSG-I Series

Technical data download

Technical data downloadRCSG-I series flexspine is cup-shaped standard structure, the input shaft directly fits with the inner hole of the wave generator, and the connection is generally used by the connection method of fixed at the rigid wheel end and output at the flexspline end through flat keys.

Product Features

- Cup-shaped one-piece cam structure

- Compact and simple design

- No backlash

- Coaxial input and output

- Excellent positioning accuracy and rotation accuracy

-

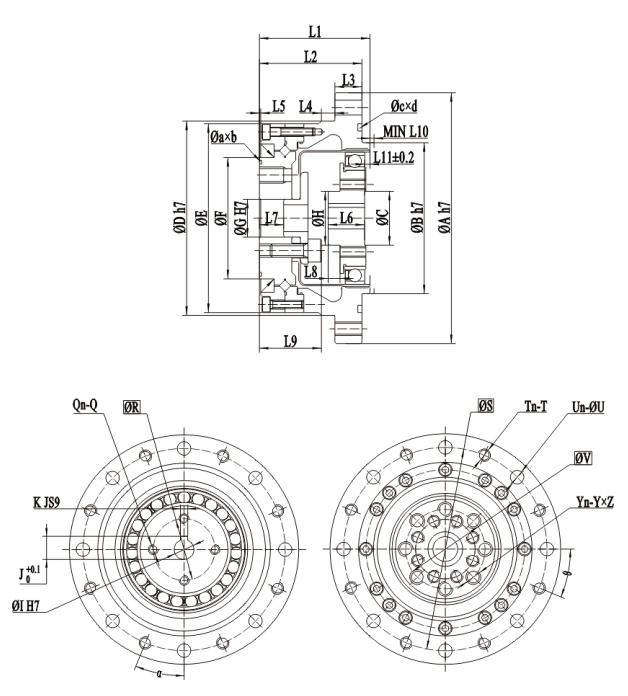

RCSG-II Series

Technical data download

Technical data downloadRCSG-II series flexspline is a cup-shaped standard structure, and the input shaft is connected to the wave generator bore through a cross-slide coupling. It is generally used with the connection method of fixed at the rigid wheel end and output at the flexspline end.

Product Features

- Cup-shaped standard structure

- Compact and simple design

- No backlash

- Coaxial input and output

- Excellent positioning accuracy and rotation accuracy

-

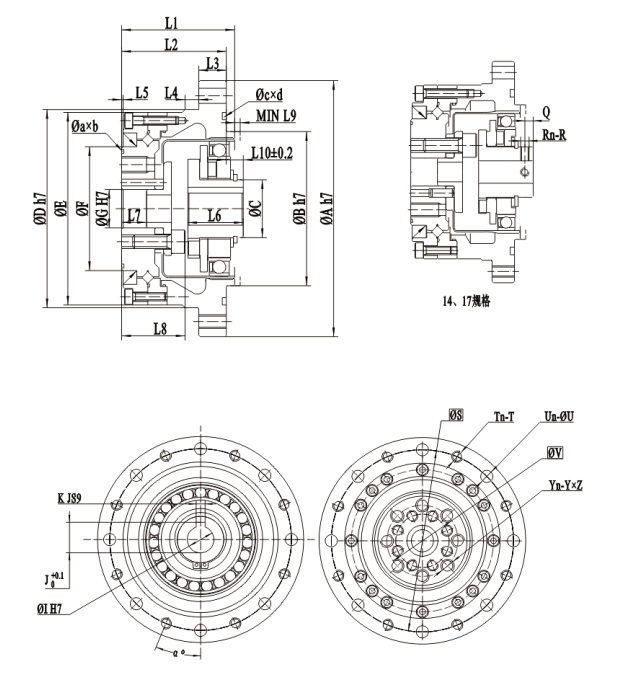

RCSG-III Series

Technical data download

Technical data downloadRCSG-III series is composed of three basic parts, including flexspline, circular spline and wave generator. The flexspline is cup type standard structure, and the input shaft is directly fit with the inner hole of wave generator, connected by flat key or set screw.

Product Features

- Three basic components

- Compact and simple design

- No backlash

- Coaxial input and output

- Excellent positioning accuracy and rotation accuracy