RHSG Hat-shaped Strain Wave Gear

Harmonic gear transmission principle

Harmonic gear transmission was invented by American inventor C.W. Musser in 1955. It is a new type of transmission method that uses the elastic deformation of flexible components for motion or power transmission, which breaks through the mode of mechanical transmission using rigid component and uses a flexible component to realize mechanical transmission, thus obtaining a series of special functions that are difficult to be achieved by other transmissions. Its name comes from the fact that the deformation process of the middle flexible component is basically a symmetrical harmonic. In addition to the Soviet Union, this kind of transmission is called wave transmission or flexspline transmission, the United States, Britain, Germany, Japan and other countries are called "harmonic transmission".

Advantages

Harmonic gearing has some advantages over traditional gearing systems:

No backlash

Compactness and light weight

High gear ratios

Reconfigurable ratios within a standard housing

Good resolution and excellent repeatability (linear representation) when repositioning inertial loads

High torque capability

Coaxial input and output shafts

High gear reduction ratios are possible in a small volume

Applications

Strain wave gears are widely used in robots, humanoid robots, aerospace, semiconductor manufacturing equipment, laser equipment, medical equipment, metal processing machinery, drone servo motor, communication equipment, optical equipment, etc.

-

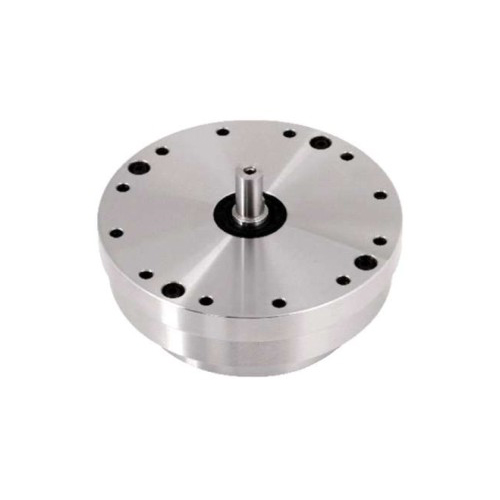

RHSG Strain Wave Gear

RHSG Strain Wave Gear

-

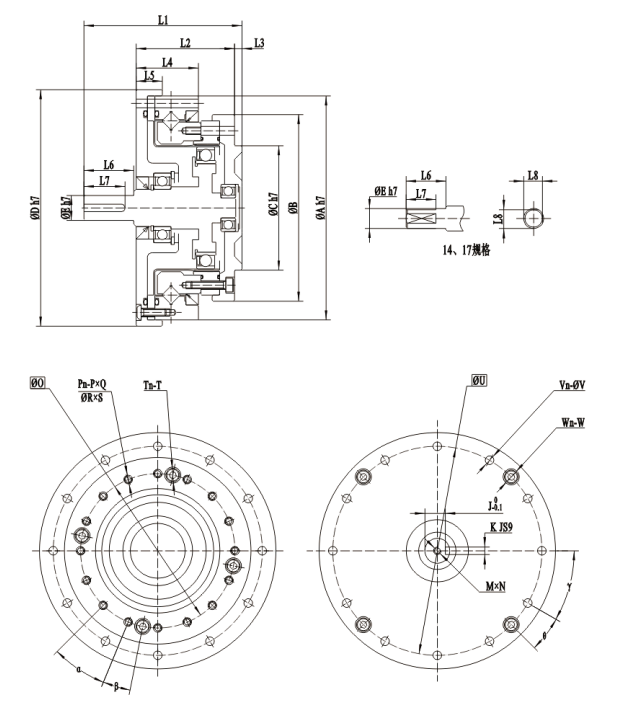

RHSG-I Series

Technical data download

Technical data downloadThe RHSG I series is a standard structure with hollow flanged edge and hat shape. Generally, the connection method of “fixed at the rigid wheel end and output at the flexible wheel end” is used.

Product Features

- Flat shape

- Compact and simple design

- No backlash

- Coaxial input and output

- Excellent positioning accuracy and rotation accuracy

-

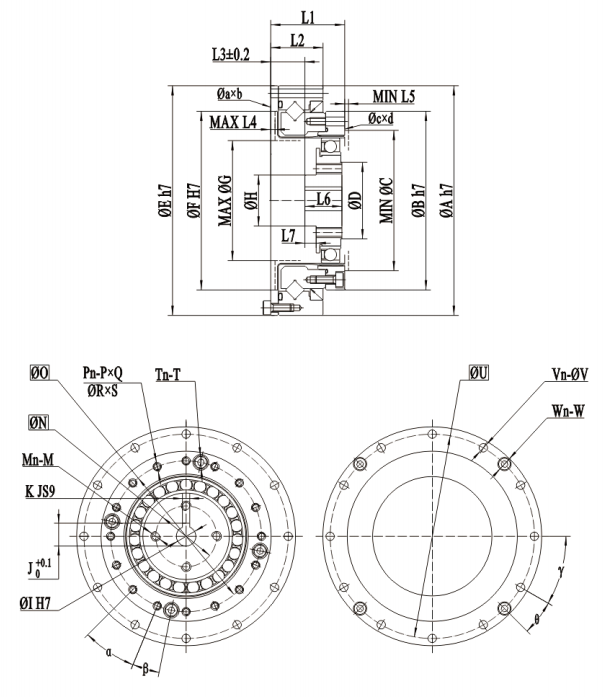

RHSG-II Series

Technical data download

Technical data downloadRHSG-Ⅱ series flexspline is a hollow flanged standard structure, the whole machine has a compact structure, the input shaft is connected to the inner hole of the wave generator through the cross slide coupling. It can be used in the connection mode of fixed at the circular spline end and output at the flexspine end, or fixed at the flexspline end and output at the circular spline end.

Product Features

- Flat shape – standard structure

- Compact and simple design

- No backlash

- Coaxial input and output

- Excellent positioning accuracy and rotation accuracy

-

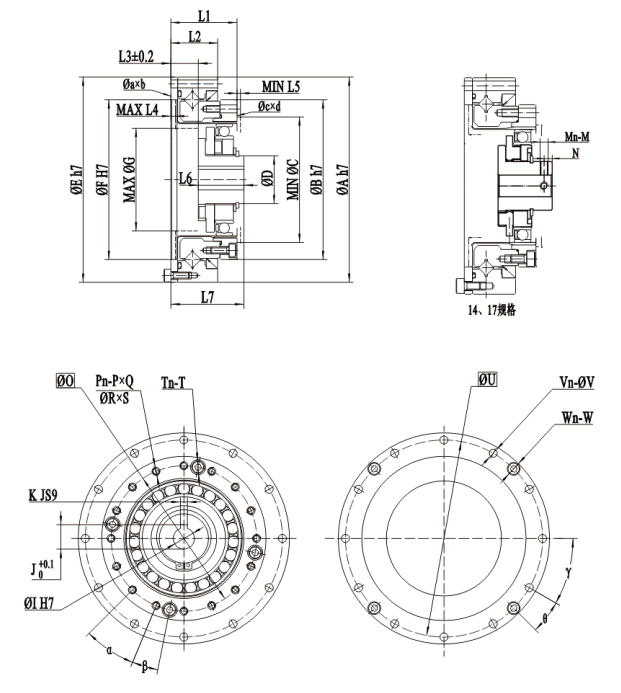

RHSG-III Series

Technical data download

Technical data downloadRHSG-III series flexspline is hollow flanged standard structure, with large diameter hollow shaft hole in the middle of wave generator cam, reducer internal design with support bearing, fully sealed structure, easy to install, very suitable for the occasion that needs to be threaded from the center of the reducer.

Product Features

- Large bore – hollow shaft

- Compact and simple design

- No backlash

-

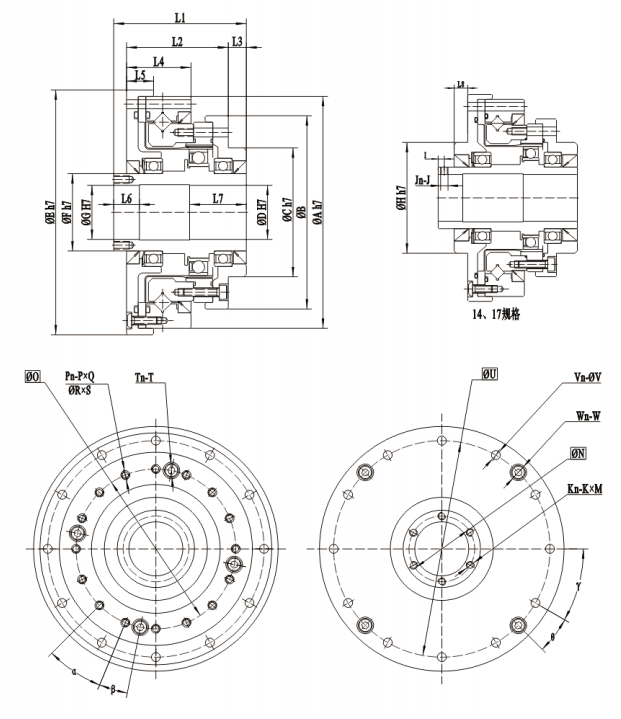

RHSG-IV Series

Technical data download

Technical data downloadRHSG-Ⅳ series flexspine is a hollow flanged standard structure, wave generator cam with its own input shaft, reducer internal design with support bearing, fully sealed structure, easy to install, very suitable for the occasions that need to install bevel gear or timing belt drive at the input end.

Product Features

- Can be used with a variety of input forms

- Compact and simple design

- No backlash

- Coaxial input and output