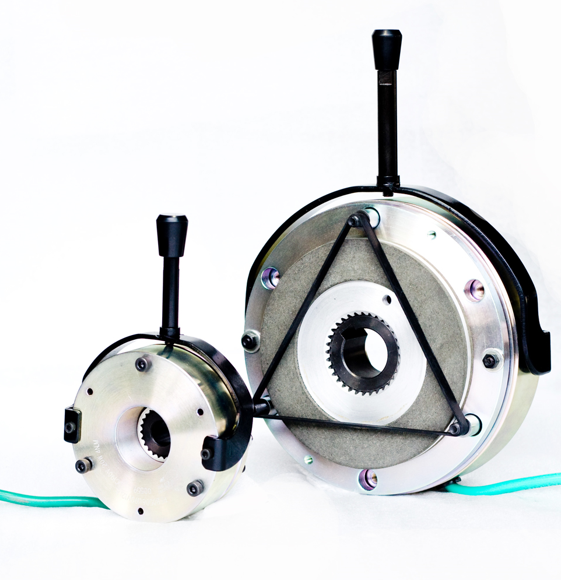

REB05 Series Spring Applied EM Brakes

Working Principles

When stator is powered off, the spring generates forces upon armature, then the friction disc components will be clamped between armature and flange to generate braking torque. At that time, a gap Z is created between armature and stator.

When brakes need to be released, the stator should be connected DC power, then the armature will move to the stator by electromagnetic force. At that time, the armature pressed the spring while moving and the friction disc components are released to disengage the brake.

Features

Rated voltage of Brake (VDC): 24V,45V,96V,103V,170, 180V,190V,205V.

Adaptable to various network Voltage (VAC):42~460V

Braking torque scope: 4~125N.m

Cost-effective, compact structure

Easy mounting

Certificated by national hoisting and conveying machinery quality supervision and inspection center type test

By selecting different modules, the highest protection level can reach to lp65

Applications

● Braking Motor

● Carpenter Machinery

● Automatic technology

● Gear Motor

● Servo motor

● Construction Machinery

● Package Machinery

● Hoisting Equipment

● Electric Vehicle

● Electric Scooter

-

REB 05 Brake catalogue

REB 05 Brake catalogue